Losing grip – Screw heads and materials

First, let me make it clear that despite the obvious (and tempting) ease, I will refrain from jokes relating to the subject of today. I am to write about screws, about different types of screw heads and materials.

It has happened to all of us, and it will happen again: some screws rust, other screws strip. In particular, the screws attaching the roll cage to the skid plate of my Bomber tend to strip. Ten screws attach the two things to each other, each time I disassemble the car, I change at least one of these in order to avoid stuck hardware. Even so, last week I had to struggle with a pair of pliers to unscrew one of them. Luckily, I managed, but it had me realize I need to change tactics. And, perhaps, screws.

First, let’s consider heads. The mast majority of screws on an RC car will be either countersunk, buttonhead or socket head cap screws. The countersunk ones can’t really be exchanged for something else, but sometimes buttonheads can be swapped for socket heads. Why then choose one over the other?

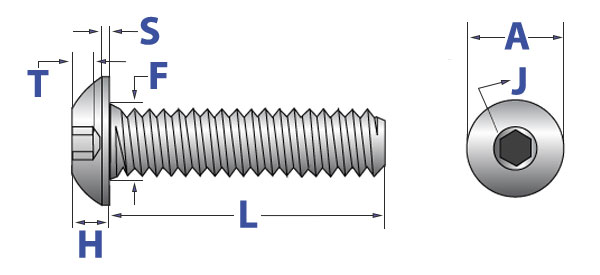

Button head cap screw

Button heads have a lower profile, which generally is more aesthetically pleasing, and also means less risk of them catching onto something. Think of the bottom of a solid axle on a crawler – you will want it as smooth as possible: button head is the way to go. Also, button heads tend to have a larger diameter than a socket head, which means less risk of them penetrating a thin material. Hence, perfect when attaching lexan panels to a roll cage. A socket head and a washer would have the same effect, but would protrude a lot more. Not the way to go, in this instance.

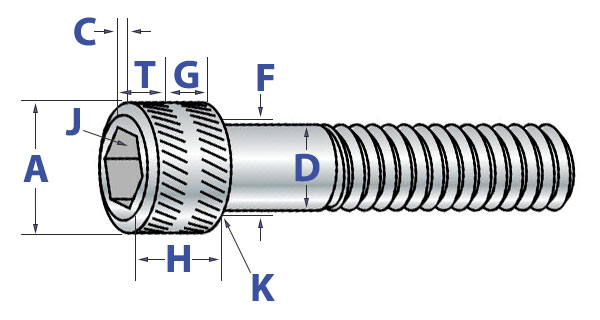

Socket head cap screw

However, the lower profile comes at a cost: strength. Button head screws are designed for light fastening applications. not where high strength is critical. This is where the socket head caps come in, they provide more strength, with less risk of stripping the hex key insert. An M3 button head will have a 2mm allen key insert, an M3 socket head cap will have a 2,5 mm insert. Larger key equals more strength. Also, should you strip the hex key insert, it’s a lot easier to grip a head cap with pliers, than a button head.

With this in mind, I have changed some of the screws on my Bomber roll cage from button heads to socket heads. Over time, I think I will do the same change on a couple of other places as well, like where the shocks attach to the front axle. This is right behind the wheels, so the extra bit protrusion shouldn’t matter, but the extra strength will be appreciated since I remove the shocks regularly.

Enough about heads, now let’s consider materials.

Hands up everyone who’s bought a stainless steel screw kit for you RC. My hand is up. I have bought a couple of these kits, essentially falling for their marketing, not really knowing what I was doing. Let me quote one of the companies offering screw kits: ”these stainless screws are A2 or 18-8 grade stainless steel, so you are getting the highest quality stainless hardware available”, and another one: ” Stainless Steel Screw Kits are far superior to the screws that come stock with your RC […] Our kits are made with the best stainless steel money can buy.”

Well… Actually, not well, since neither statement is true.

First, the A2 grade steel offered is not the highest quality hardware available, period. For example, the company behind the second quote uses both A2 and A4 grade, and A4 (marine grade) is superior to A2 in both strength and corrrosion resistance.

Second, stainless simply cannot be said to be ”far superior” to the black oxide screws that comes with most RC’s.

I have searched in vain to try and find what grade steel the big manufacturers us in their RC’s, but can’t find it. A reasonable guess is that grade 8.8 black oxide steel is used – it’s cheap and of decent quality. While it is prone to rust, the tensile strength is actually higher (just) than A4 stainless steel, and definitively higher than A2 stainless steel.

In short: stainless steel screws are only of value if there is moisture involved. And not all stainless is the same. It seems to me that most manufacturers of screw kits for RC´s, including the ones I have used up until now, use A2 steel. My experience tells me this is too soft, at least for screws that tend to get unscrewed a lot.

So, what to do? If a particular screw head tends to strip, consider changing it from a button head to a socket head. If it rusts, consider stainless, preferably grade A4. While screw kits are convenient, consider that screws are cheap, fifty to a hundred M3 12-20 mm will cost you a couple of dollars. If you buy a screw kit, have a look at what kind of steel they use. If only A2, look elsewhere. If it doesn’t specify, look elsewhere. A mix of A2 and A4 might be okay; it seems to me that some smaller screw dimensions are hard to find in grade A4. If you don’t need stainless, and want the convenience of a screw kit, check out Tonys Screws LLC. No, I am not sponsored, and haven’t used them yet. But they use grade 12.9 black oxide alloy steel, which is about as good as it gets. Very few screw kit manufacturers do. Grade 12.9 is what I will look for, as I slowly but surely exchange screws on my rigs. Again, some smaller dimensions are hard to find in this grade, in those instances grade 10.9 will do.

To read another column, hit the link.